Table of Contents

The NEJE A40630 module utilizes a top-tier Nichia light source and features fast-axis compression technology, providing an output optical power exceeding 6W. It offers a smaller focus size, higher light efficiency, and a longer service life compared to traditional 5W modules. The zoom optical design gives the module a very uniform and sharp beam, enabling it to achieve a small focus point and a well-proportioned XY beam shape, whether at near or far focus. The most distinctive feature of this module is its ability to meet the needs of users who require both fine wood engraving and cutting. Additionally, the module is capable of engraving materials such as glass, ceramic, stone, anodized aluminum, and stainless steel, as well as cutting non-woven fabric and cardboard.

Application Examples

https://www.facebook.com/photo/?fbid=8431039603620114&set=pcb.3786060768305638 a40630 6w

https://www.facebook.com/photo/?fbid=10229444305429375&set=pcb.3717645095147206

One of my newest creations, Thanks I am really loving my neje. Hope to some day had more to my two I have.

https://www.facebook.com/photo/?fbid=10229444305429375&set=pcb.3717645095147206

One of my newest creations, Thanks I am really loving my neje. Hope to some day had more to my two I have.

https://www.facebook.com/photo/?fbid=8636769413081435&set=pcb.3852560191655695

Sometimes have to creative to do my lasering lol

https://www.facebook.com/photo/?fbid=8636769413081435&set=pcb.3852560191655695

Sometimes have to creative to do my lasering lol

Features

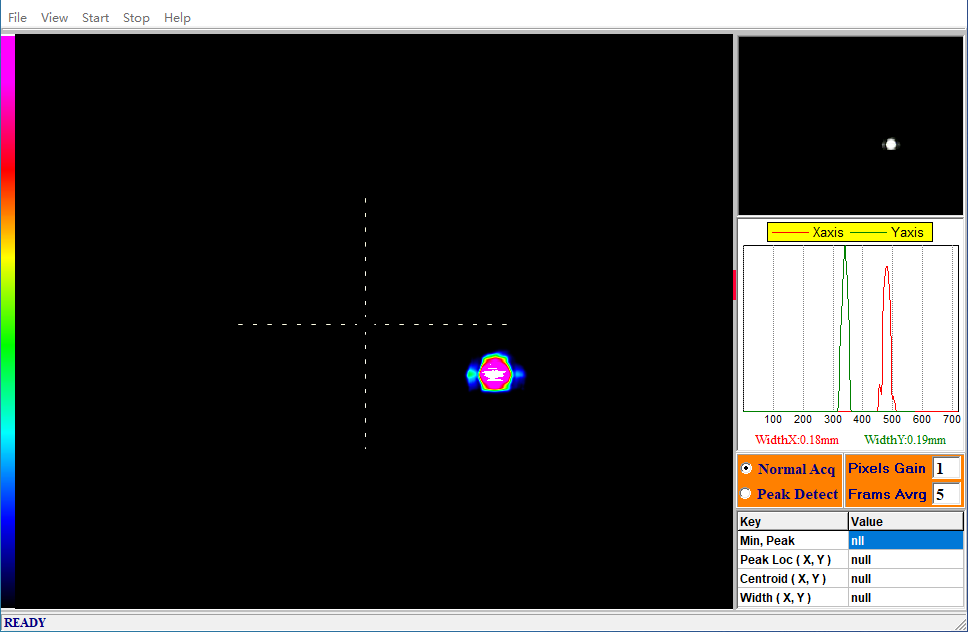

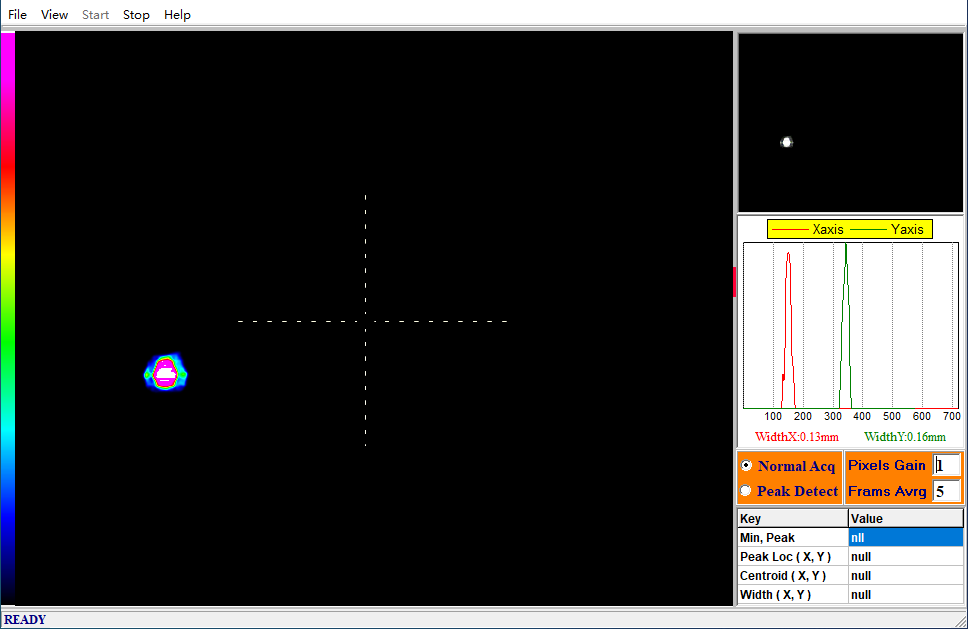

Adjustable focus, showcasing different performance

Adjustable focus, showcasing different performance

The A40630 is an adjustable focus module. Guide image above is a guide for the best adjustment settings. You can use a flat-blade screwdriver to adjust the focus position. Proper focus selection is a critical factor for cutting. You may need to try more few times. In addition, adding air assist will enhance cutting and engraving results, resulting in cleaner edges and enhanced cutting thickness and cutting efficiency.

Module: A40630, When focusing to 55mm position (lens-to-focus distance), you can get a 0.18×0.18mm focal point and be able to cut material up to 18-20mm (requires accurate focus, 0.6-1.5mpa air assist to align the cut).

When the focus is adjusted to about 33mm from the light outlet with a flat-blade screwdriver, you can get a focus of 0.13*0.13mm, which is suitable for engraving and fast cutting of materials smaller than 10mm.

Quiet design

NEJE module driver has built-in control program. The module uses high-life and high-speed double ball bearing fans. After more than 10 years of development, it has achieved very reliable electrostatic protection, high life and silent experience. The built-in driver can intelligently identify TTL signals and temperature sensing to ensure the reliable working temperature of the module while keeping the fan in a dynamic balance and silent state.

Air Assist

Air assist is a complex and specialized field for laser equipment, which often requires different air assist solutions based on the materials, maintenance and process effects we actually operate.

A: When dealing with regular engraving and small amount of cutting tasks, we can use the module's own cooling system to protect the lens through airflow, which can largely eliminate the need for an additional AOC oxygen machine to protect the lens.

B: The needle-tube high-pressure air nozzle can use oil-containing and water-containing air sources as air assist. Through the high-pressure gas assist, when cutting wood or HDF boards, it can cut more efficiently and make the edges more.

C. The cavity-type air-assisted configuration is suitable for oil-free and water-free gas sources. Compared with the needle-tube gas nozzle, it consumes relatively more gas, but is easier to operate.

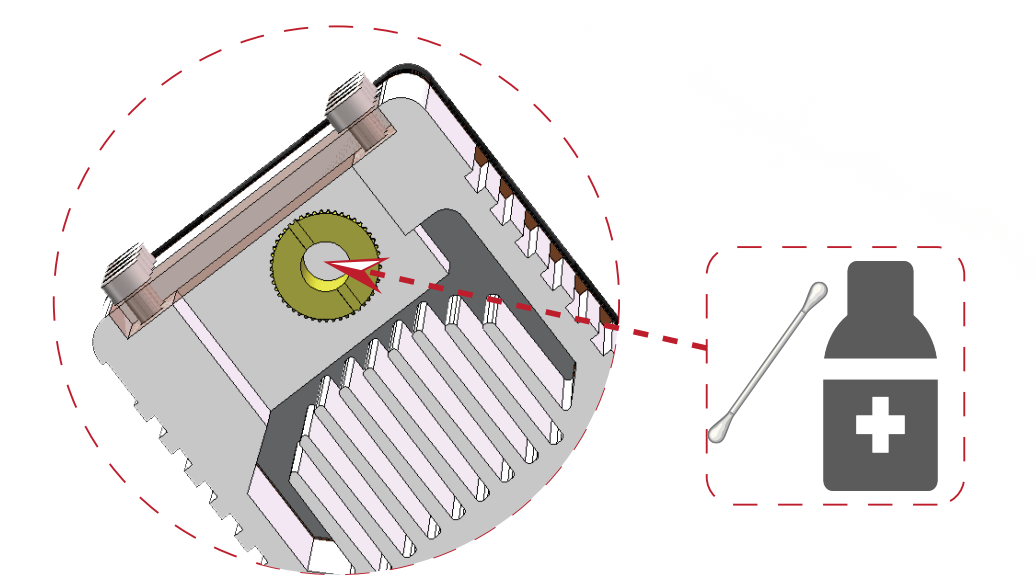

The above three solutions can protect the lens and enhance cutting to a certain extent, but the lens also needs regular maintenance, which can be cleaned with alcohol and cotton swabs.

Database

plywood 2mm cut ———— 160mm/min ,S1000,1 pass

plywood 3mm cut ———— 120mm/min,S1000, 1 pass

plywood 4mm cut ———— 100mm/min ,S1000,1 pass

plywood 8mm cut ———— 120mm/min,S1000, 3 pass

plywood 18mm cut ———— 120mm/min,S1000, 8 pass

birch ply 3mm ———— 240mm/min ,S1000,1 pass

MDF board 3mm cut ———— 120mm/min ,S1000,2 pass

MDF board 5mm cut ———— 120mm/min ,S1000,4 pass

MDF board 8mm cut ———— 120mm/min ,S1000,5 pass

black acrylic plate 3mm cut ———— 120mm/min ,S1000,2 pass

black acrylic plate 5mm cut ———— 120mm/min ,S1000,4 pass

NOTE: The data below need to add air assist correctly (0.6-1.5mPA) with laserGRBL or lightburn; lightburn: 60mm/min=1mm/sec,S1000=100% Power (In lightburn, the unit is 60mm/s)

Specification

Radiator Size: 40 x 50 x 60 mm

Weight: 204g

Speed of the Fan: 10600RPM(Double ball bearing)

Interface: PH2.0 4Pin

Drive Design: Built-in

Input: 12V 2A +

Optical Power: 6W +

Wavelength: 450nm

Laser Class: Class 4

Number of Diodes: 1

Light Source: 1 X LD + FAC Tech + C-Lens

Focus Spot: 0.13×0.13mm - 0.18xo.18mm, focus on 33mm: 0.13 x 0.13 mm,focus on 55mm: 0.18 x 0.18mm

PWM Input: VPP(3.3-12V), Recomend 1KHz

Quiet Design: Drive the built-in control ic, judge the working state and adjust the fan work.

Max Cutting & Carving Depth: 18mm (The data is tested by NEJE users, and it needs to be done under more accurate focusing and adding correct and certain strength of air assist.)

Brushed Stainless Steel Carving: Yes

Mirror Stainless Steel Carving: Yes

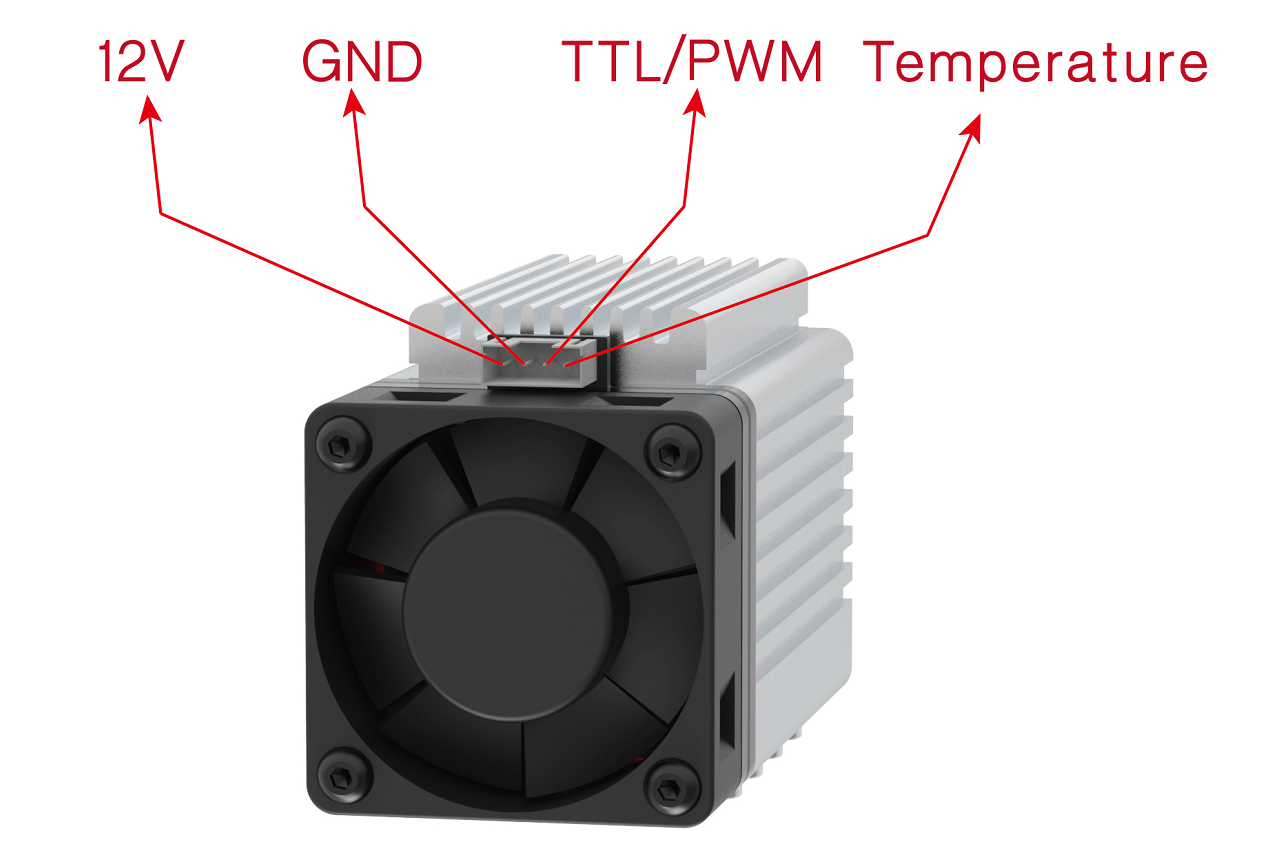

Interface

12V: Power positive .

GND: Power ground or power negative.

TTL/PWM: TTL = PWM, input 3.3V~12V to turn on laser module, conect to GND to turn off laser module.

Temperature: do not connect, please ignore.

Connect 12V and GND pin to 12V power, ensure the power adapter is sufficient, 5A is recommended.

Connect TTL/PWM pin to your control board PWM output pin.

Test Board

Maintenance

Although this module adopts internal air-assisted design, long-term use may not prevent dust or a small amount of smoke from affecting the lens. It is recommended to clean the lens with a clean cotton swab. Dust or smoke may overheat the lens and cause the lens to burn out. Re-acquire the lens Will delay your use.

FAQs

Inferior power supply leads to the problem of laser power drop!

About PWM signal specification.

How to distinguish my laser module types ?

How to make laser module work with your control board ?

How to check my cable connection is properly

For more information, please search in NEJE Document